Head north down Mcdonald Park Rd. then turn right down an unmarked fire-lane just before the Sidney Feed Barn and you will find Titan Boats.

After accidentally walking into the engineering team’s office, I discovered Titan operates in several buildings…specifically 5,400 sq. feet of fabrication space and another 1,600 sq. ft shop for outfitting & rigging facilities. Their fenced yard covers over 21,000 sq. ft.

Once I got my bearings, I met Titan General Manager, Paul Smith. Titan is a family run business. Here we go…Paul’s son in-law is Titan Founder and President, John Stanners. John’s father, Robert Stanners, generates technical drawings for new builds, Jonathon Stanners, John’s son, is a Marine Systems Technician. Jamie Stanners, John’s nephew is Marine Systems Lead Hand. And Titan Organizational Development Manager, Jennifer Michell, is John’s daughter and Paul’s granddaughter.

From a modest start

The company started in a single-bay garage. From there they moved a few times before settling in their current space. And they have plans to move again. This time into a custom-built space to fit their growing business.

For over 20 years, Titan has built world-class rigid hull inflatable boats. They have earned a reputation for incredible performance and quality. Their boats start on a stock platform, a 17′-50′ aluminum hull with neoprene hypalon inflatable tubes. From there the boats become customized vessels based on the tasks their customers need to perform and the conditions where they operate.

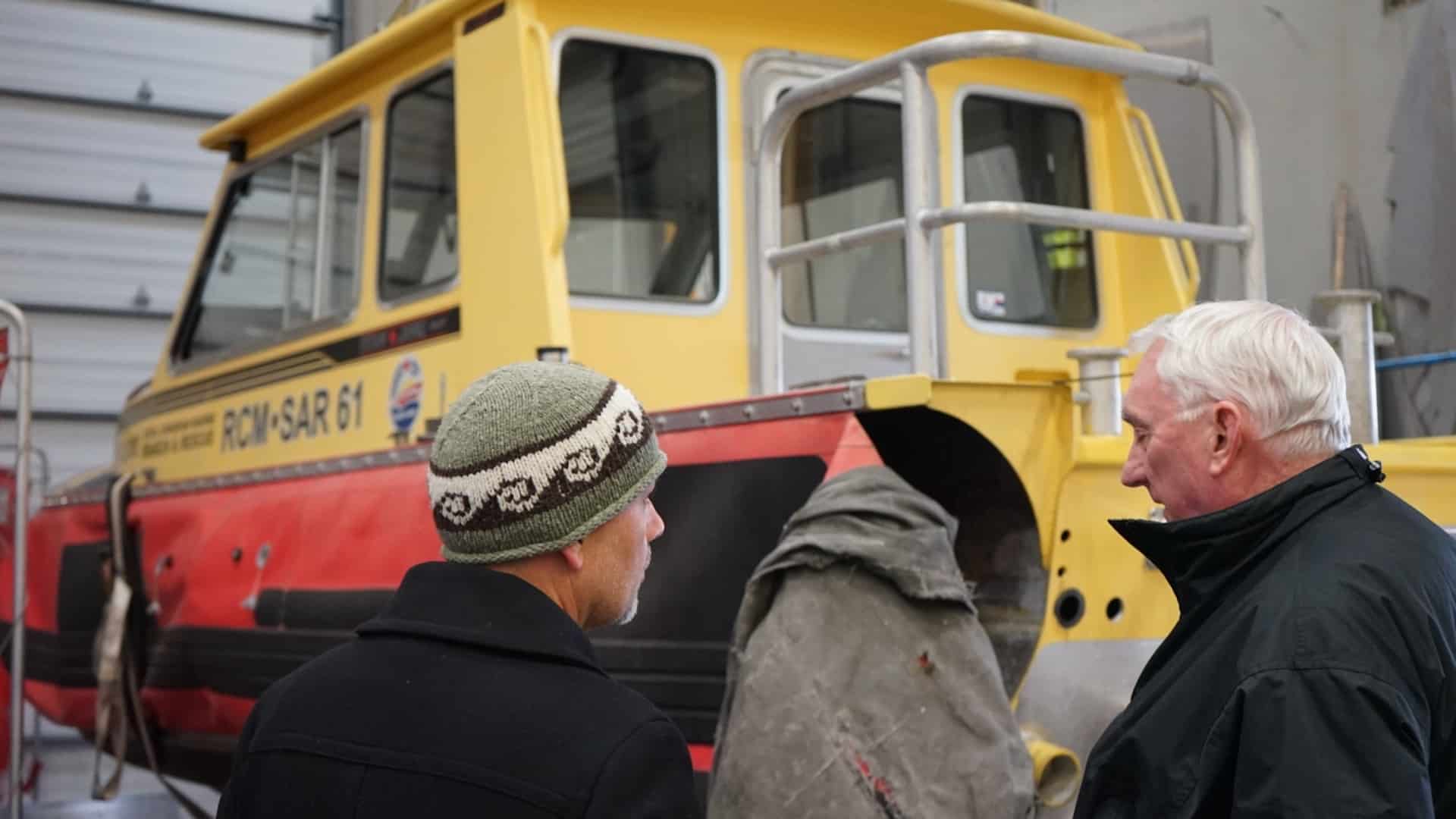

So, who are their customers? Mainly, they are local, national and international patrol and enforcement services including RCMP and provincial police, fisheries, Environment Canada, RCM-SAR and Customs Canada (Canadian Border Services).

In 2016, Titan built two police vessels for Slovenian waters. The $1-million contract with the police force helped boost Titan into the European law-enforcement market.

Titan employs people with a range of expertise. Everything including computer design, fabrication, painting, outfitting and rigging, deck work and office work is done in house. There is high regard for their quality workmanship across the industry.

High quality craftsmanship

They stand behind their product, providing a lifetime warranty on their craftsmanship. But, they often see their products return to them because another important part of their business is after-market work.

Boats waiting to get refitted, upgraded or repaired filled the yard. Some were there just as part of a regular service plan. Others were there because they suffer wear and tear. As Smith made very clear, Titan boats work very hard, and sometimes their operators need to put the machine in a tough spot.

As the company continues to grow and celebrate success, Titan shares the same challenges as other business owners on the Peninsula – affordable housing, transportation and the impact of the Employer Health Tax. Out of the 34 employees 7 commute from Mill Bay, Shawnigan and the Westshore.

Titan is an excellent example of a home-grown business, producing an incredible product for a global market.

0 Comments